Ever wondered how your favorite flaky croissants or delicious apple turnovers are made from the bakery? It is a special procedure called pastry production line! Juheng puff pastry production line is where recipes are divided into work steps so that a variety of machines can create tons of scrumptious pastries simultaneously. After preparing the pastries, they are meticulously packaged and shipped for sale.

Pastry chefs mix the dough to start. They combine all the ingredients and then transfer portions of dough to Juheng Puff pastry production line. This is a long process from dough to finally exchanging into another machine. These are varieties which can be made in bread machines, which actually roll the dough flat and then cut it into fun shapes or add fillings inside them. The pastries are then set to be baked in the oven.

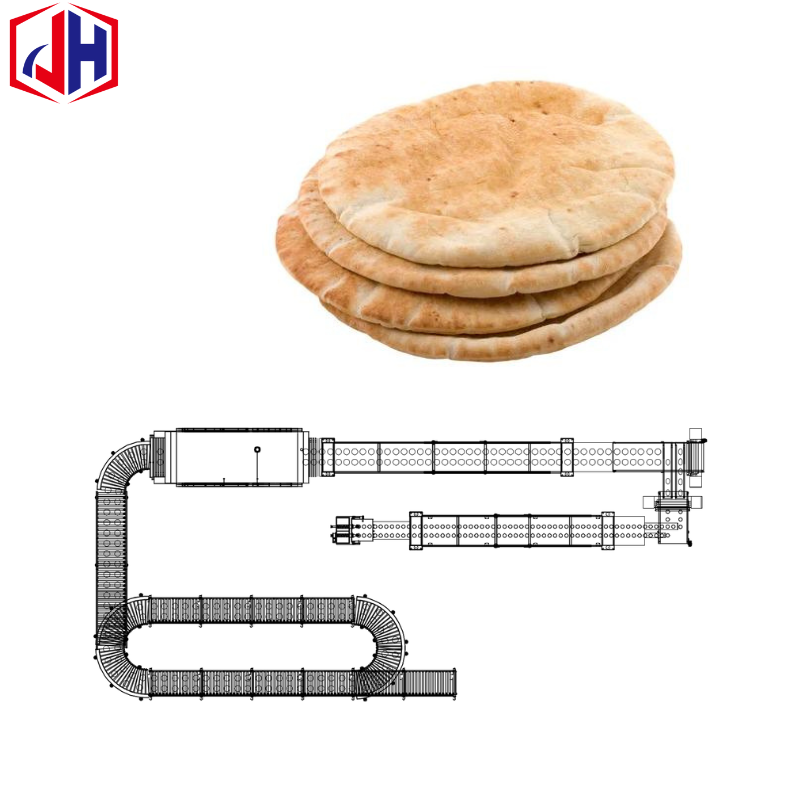

Baking is methodical, accounting for the exact proportions and detailed description of steps. It needs the right concoction of ingredients, with a sprinkle of required temperature fluctuations and exact minutes on flame-to have them edible. Dough has flour, water, sour cream and a combination of sugar, butter, yeast with juice. Once the dough is made it needs to sit for some hours till perfect. Once it's had a chance to rest, you can roll it out and cut into shapes for other pastries such as croissants, turnovers or Danish. Filled and shaped, they are baked until golden brown with lovely flakey layers making them so yummy to eat with the help of Juheng Diverse pastries production line!

There is a whole team of skilled people working together behind the scenes, in front of the pastry production line. A team of pastry chefs, bakers or machine operators with the end aim that all goes to make a delicious and popular pastries. It's up to the chefs from here picking the finest ingredients and assisting in a thoughtful preparation of dough. The oven is heated to the correct temperature by bakers, who keep a sharp eye on pastries as they bake. It is the responsibility of puff pastry production line operators to operate machines that cut and shape dough accurately so all operations can run well.

The baked and cooled pastries are then placed in boxes on trays. This will ensure they are fresh and protected for shipping. When filled, the pastries are transferred to grocery stores and cafes where it is sold. The Puff pastry production line is something of scientific research, needing cautious planning and group work to have successful results. And the whole thing requires a ton of hard work to ensure that every single pastry is just right and tastes great for all who will eat them.

We're Pastry production line to developing lasting relationships with our customers We provide comprehensive after-sales services including installation education and regular maintenance Our team is always available to assist you with any queries or concerns We are also investing continuously in technology research and development to enhance our services and products You'll be partnering with an organization committed to your development and success if you choose us

We can provide pastries and flatbread production lines that are completely customizable. The products we design are in close collaboration with our customers making sure they're perfectly aligned to your production needs. From Pastry production line to final packaging, we tailor every aspect of our line to optimize efficiency and product quality.

We are a daring business that is 8 years old and has rapidly established itself as a rising star in the world of food Our team of Pastry production line is always expanding their expertise and knowledge ensuring we stay on top of technological advancements in the industry Our commitment to constant expansion means we're always evolving our skills adjusting and advancing to meet the changing needs of our clients

We insist on quality over all else Our production lines are constructed up of only the highest-quality components and materials We also employ strict quality control throughout our entire production process We are committed to meeting Pastry production line This ensures that every product from our manufacturing facility meet most stringent standards This will enhance the brand's image and improve satisfaction among customers