Do you wonder about how your food gets to the plate? That is likely a very long journey, and more often than not it involves way too many humans. This process frequently begins in an orchard, on a vineyard or at the ranch. However, have you ever stopped and thought how the food is made before it gets to your local grocery store? This involves numerous steps and can be quite fascinating to know!

Nowadays, food is mostly produced in large factories with the help of machines. All these machines are brought together in a particular process called the production line. Food is produced in a process along an assembly line. Every machine has a task, and they work together in order for the factory to be able manufacture large amounts of food wisely. This way, the Juheng food processing industry equipment can serve food to many people in one go which is really necessary.

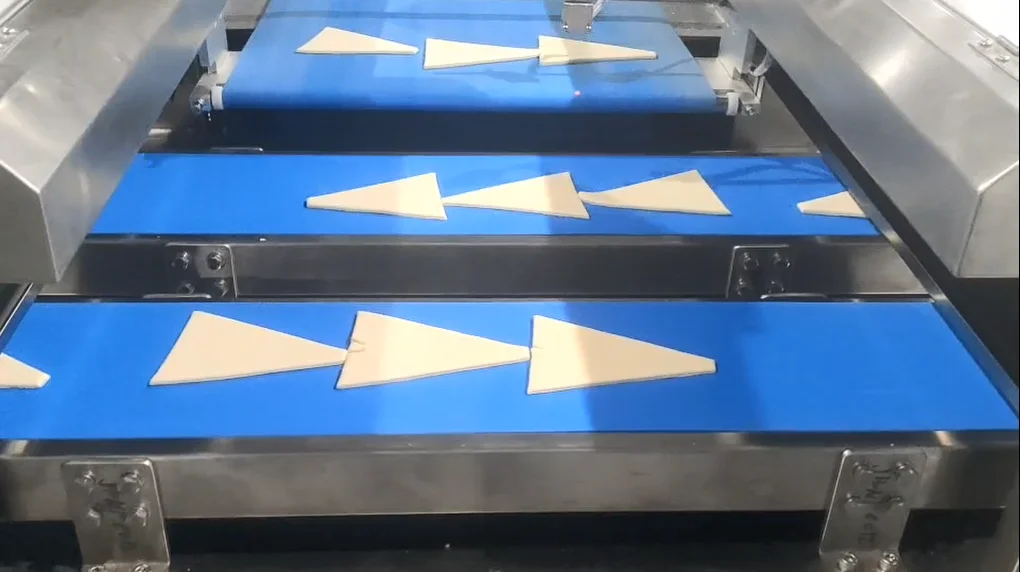

What happens inside a food factory. The Juheng equipment for food processing had large bowls with no doubt tasty ingredients, flour, sugar and eggs to name only three in the image. This dough is then extruded in various shapes on a conveyor belt. This is where the fire comes in! Then the shapes are put into an oven where they are baked to perfection. They need to cool down once they have baked, before you can pack them. The cookies or cakes are then packaged beautifully and sent to the grocery store, where you can buy them and enjoy!

We need to make sure we are following important rules so that our food is safe. The people working inside the factory must then put on special clothes to keep food clean - and they have to wash hands before starting work. Being wrapped is vital to prevent contamination, which might lead to illness in food. The machines and the whole factory are cleaned frequently to keep everything safe.

To ensure that the food is safe for consumption, as well desirable to eat, it has to respect a set of rigorous standards. We have these laws to protect us and make sure we eat the highest quality food. Juheng processing food equipment will also save resources and the environment, which we shall all take care of. Aligning their doors towards saving energy, water and other natural materials while making food. The solution here they are apparently urged to use properly energy and water = better for the planet.

The standards will also look at the quality of ingredients used in producing food. Fresh ingredients care very important to use as every dish being included in your diet needs not only taste nice but must be edible. These materials which are also passed as industrial products by machinery are controlled heat to ensure that the raw material is not wrong or in laceration. Burn examined the classification of food 125 years ago, and according to today's Food laws that our ingredients must meet a standard for safety due their guidelines.

New food technology provides us with increasingly better ways to grow whatever we want. That way, factories can operate more efficiently because they produce healthier meal options for all. Now some companies are making biodegradable packaging from recycled materials but not nearly enough. Some are lowering salt, sugar and other additives in their recipes but retaining the deliciousness we all love to eat.

We insist on quality over all else Our production lines are constructed up of only the highest-quality components and materials We also employ strict quality control throughout our entire production process We are committed to meeting Production line food industry This ensures that every product from our manufacturing facility meet most stringent standards This will enhance the brand's image and improve satisfaction among customers

Production line food industry are a daring company with an age of eight years old that has quickly established itself as an emerging star in the field of food Our team of committed professionals are always seeking to improve their skills and knowledge making sure we're ahead of the curve in technological advancements in the industry Our dedication to continual expansion means that we're constantly improving by adapting and re-inventing to meet the ever-changing needs of our customers

We're Production line food industry to developing lasting relationships with our customers We provide comprehensive after-sales services including installation education and regular maintenance Our team is always available to assist you with any queries or concerns We are also investing continuously in technology research and development to enhance our services and products You'll be partnering with an organization committed to your development and success if you choose us

Recognizing that each Production line food industry is unique We offer highly customized production lines for pastry and flatbread. We collaborate closely with customers to make sure that our products match your production needs. We improve the efficiency of our production line by adjusting every element from handling materials to packaging.