Many enjoy eating puff pastry with delight. Now this pie crust is light and flaky and has that yummy buttery flavor that sets it apart from other recipes. Below is the recipe with many tips and tricks to make perfect puff pastry. But making it by hand can be a tough nut to crack, along with being fairly time consuming as well. That is why there are dedicated machinesopp pastry processing lines. I use mine for when do not have much time but want to make puff pastry, it just makes life SOOO EASY!

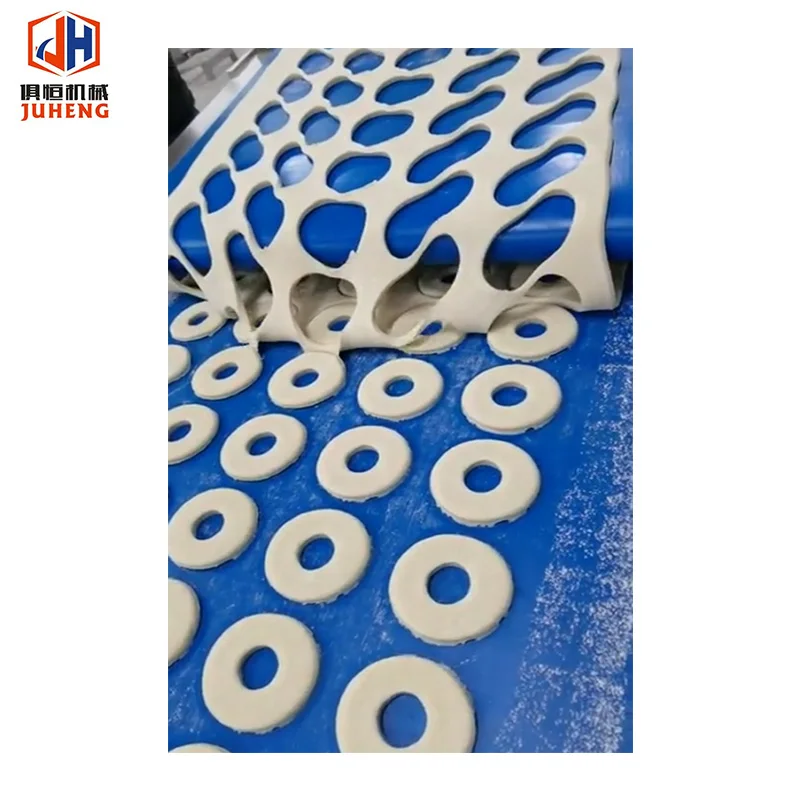

For creating the perfect puff pastry, bakers should know how to execute it and what techniques they have to follow. Making a puff pastry is much more complex than just mixing its constituents. It consists of laboriously layering dough, a process much longer and complicated than most pie crusts can withstand but has become easier with special machines for making puff. These machines automate some of the back-breaking labour involved with baking, greatly reducing the amount of time spent in doing so while also streamlining this process to make it quicker and cleaner.

High-speed puff pastry machines are very useful when it comes to the faster preparation of pastries. They are capable of baking a lot of pastry in short interval. This is especially beneficial for wholesale bakers that bake large amounts of pastries a day. Also, bakers are less stressed which isn't hurt by the fact that some of the work is being done by machines. It helps them to concentrate more on their works and work efficiently.

If you are baking lots of pastries its very important that all should taste same and also look good. The puff pastry processing line is ultimately what ensures the consistency that every one of those pastries are exactly the same as last time. Those machines help in keeping everything consistently as they also prevent human errors. Since bakeries are expected to produce consistent, delectable treats with every batch they sell.

How Can Puff Pastry Forming Machine Increase The Quality Of Your PastriesAuto puff pastry machine. It will help to maintain proper order in the kitchen, and you also preserve a uniform quality of your pastries. If the machines are doing all of this work, bakers can use their time to develop new recipes. It helps to keep their customers interested by being able to surprise them with interesting new treats that they are going to adore.

Our primary goal is to prioritize quality above all else We only use high-quality materials and components for our production lines and puff pastry processing line stringent quality control measures throughout the production process We're committed to achieving European standards This ensures that every product from our manufacturing facility meet most stringent standards This can boost the reputation of your company and increase the satisfaction of your customers

puff pastry processing line are committed to building a long-term relationship with our customers That's why we offer comprehensive after-sales service which includes installation training and regular maintenance We're always available to help you with any questions or concerns We also invest continuously in research and technology development to improve our products and service By choosing us we're working with a company committed to your success and expansion

We are a spirited company with a history of 8 years that has quickly established itself as a rising star within the puff pastry processing line Our dedicated team is always improving their skills and knowledge to ensure we remain at the forefront of technological advancements within our industry Our commitment to continuing growth means we're always improving our skills adjusting and advancing to meet the ever-changing needs of our clients

Knowing that every business is unique, we offer highly customized production lines for pastry and flatbread. Our products are designed by working closely with our customers, ensuring they perfectly align to your production needs. From handling of materials to the puff pastry processing line, we can tailor every aspect of the production line to optimize efficiency and product quality.