Do you even know what roti paratha is? It is a tasty flatbread that really tons of people like, especially in Asia. Roti paratha doesn't demand any fancy ingredients, just flour water oil. Its a bite out of how because it has many layers and due to that its crispy so tasty. To find out how to make roti paratha and why it is consumed by a lot of people, proceed with the article

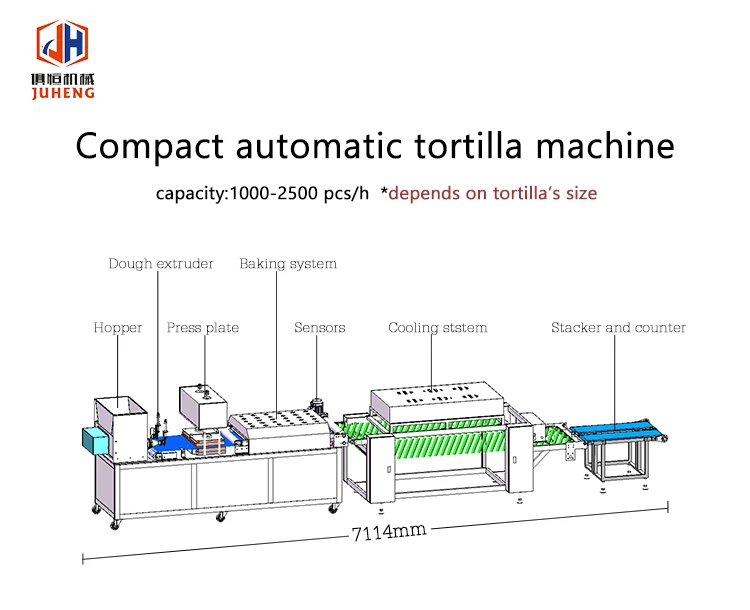

“Roti Paratha is produced in factories via a production line. This Juheng roti canai production line is a production line where multiple machines form the roti paratha. A machine is seeing running and mixes flour, water, oil etc to get a dough. And, this soup is made into a dough which is rolled and cut in to small pieces for further proceedings. The dough is then rolled and stretched to make it as thin with layers of pastry. In the end, its half boiled and baked toasted through a roti paratha bakker till hard golden brown then gear-up for packaging to send out/store.

A roti paratha factory — is a huge building, where for each stage of preparation there are separate rooms. This is the process of mixing flour, water and oil to make dough kept by workers in their first room. The dough is then taken to another room where it's flattened and chopped in small pieces. The pieces are then set into a third room. There, they are rolled meticulously and extended to flatten with one another. The final room is the giant oven that they use to bake their roti paratha which can then be packed up for stores

Roti paratha is a crispy, flakey bread that is rolled out incredibly thin. It is a skill that requires both practice and execution competence. Some factories have machines that can press out the dough while others do this by hand. Both methods have their own benefits and can yield a tasty roti paratha.

One more critical component to producing perfect roti paratha is the temperature and humidity within factory grounds. The dough should be kept at an even candy temperature and humidity to have perfect roti paratha. In certain factories, there are specific climate-controlled rooms to ensure that the dough ferments perfectly. Juheng roti canai making machine is this meticulousness that guarantees the gratification in every bite of roti paratha.

The flour, water and oil are mashed together into soft dough as the first impression of a roti canai fIattening process. Next, the dough is flattened and shaped into little bite-sized bites. Then rolled out and stretched until they are very thin with many layers that will provide a crispy dough when baked. The roti paratha is then baked in the oven until it becomes crispy and golden brown.

When the roti paratha is ready, it is placed into boxes and taken to stores for sale. Certain units store the Juheng roti production line by freezing it so that they last for a longer time. This way, it is so that everyone can buy and to enjoy anytime they want be as breakfast or lunch or dinner.

Roti paratha production line are committed to building a long-term relationship with our customers That's why we offer comprehensive after-sales service which includes installation training and regular maintenance We're always available to help you with any questions or concerns We also invest continuously in research and technology development to improve our products and service By choosing us we're working with a company committed to your success and expansion

We are a daring business that is 8 years old and has rapidly established itself as a rising star in the world of food Our team of Roti paratha production line is always expanding their expertise and knowledge ensuring we stay on top of technological advancements in the industry Our commitment to constant expansion means we're always evolving our skills adjusting and advancing to meet the changing needs of our clients

We are a company which Roti paratha production line quality at the top of its list Our production lines are made with only the top-quality components and raw materials We also employ strict quality control throughout the entire manufacturing process We work hard to align ourselves with European standards This ensures that every product we produce meets the highest standards of quality which boosts your brand's image and satisfaction of your customers

We can Roti paratha production line pastries and flatbread production lines that can be custom-designed. We collaborate with our customers to make sure that our products meet your production requirements. We maximize the effectiveness of our manufacturing line by customizing every step including material handling and packaging.