Hasta Chapatis! Naan is one type of flatbread which people usually like it having while eating either in India or Pakistan, indeed its part of anyone finger licking Asian cuisine. They were a common addition of foods and are known for their creamy texture as well delicious smell. Realistically, though — at the speed of life gets going in families where chapatis are pumped out like breathing air rolling by hand is not only a pain but it can also be very difficult. Rolling out dough, cooked each chapati one by one, and made sure that all of them tasted good. It can be tiring! But is it if we make chapatis through some specified machines like food production line from Juheng then the entire process can be much simpler and more advantageous for all.

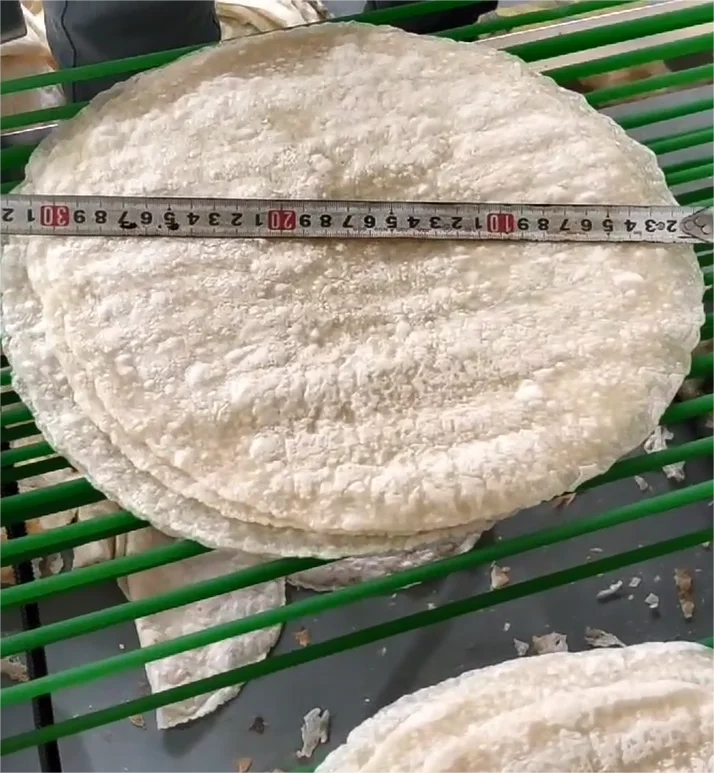

Little can stop a chapati making machine from rolling out warm, delicious rotis and fast. It is a machine that performs many critical functions and for the dough, it brings together all of those ingredients. Chapatis are toast in a toaster to done. Well, that definitely makes a lot less work for the people in question! All the chapati produced by this production line food industry from Juheng has consistent size in diameter, shaped round and have been baked to last due to a long time for store or at restaurant. This across the board standardization should imply that any customer is sure of what they are gaining with their chapatis.

This is very much useful in industrial base of products where chapatis have to be made. For example, say there is a restaurant which have many chapati orders along with other items. No body has to take longer since mass Chapatis machine turns the batch for you. It can take tens of chappatis at a time instead of cooking just one chapati so opt for production line food from Juheng.

The advantages of the Chapati-making machine for business are numerous. It increases the business turnover as they could sell chapati much quicker. The Automatic Flat bread Production Line supports the growth and prosperity of business in this competitive market arena.

There are a lot of varying ways in which different enterprises can find huge advantages if they install their own dedicated production line for chapati. We can adjust this line based on how many chapatis we want them to prepare that too in few seconds as it is filled automatically. This way preparation of chapatis is faster and resources are not wasted. With the industrial flatbread line, workers are liberated to do other operations (instead of being tied in a kitchen making pasta for hours). Highly productive lines mean more work in less money or no loss of cash, which creates a chance for their (business) to entering the controversial market.

At our core we insist on quality over all else The production lines we use are built from only the best components and raw materials We also follow strict quality control throughout our entire manufacturing process We're determined to meet European standards This guarantees that all products from our manufacturing facility meet most stringent standards This will enhance the brand's image and Chapati production line among customers

We can provide pastries and flatbread production lines that are completely customizable. The products we design are in close collaboration with our customers making sure they're perfectly aligned to your production needs. From Chapati production line to final packaging, we tailor every aspect of our line to optimize efficiency and product quality.

With a spirited 8 years old company we've swiftly established ourselves as a rising star within the food production industry Our team of dedicated professionals are always seeking to improve their expertise and knowledge making sure that we are on Chapati production line of industry developments Our commitment to continuous expansion means we're always evolving by adapting and re-inventing to meet the changing needs of our customers

Chapati production line are committed to building a long-term relationship with our customers That's why we offer comprehensive after-sales service which includes installation training and regular maintenance We're always available to help you with any questions or concerns We also invest continuously in research and technology development to improve our products and service By choosing us we're working with a company committed to your success and expansion