This is a very neat tool related to lamination of dough for bakers! From classic loaves to fluffy bagels, these machines are truly great when it comes to making baking fun-filled and fast. Today we will explore how these amazing machines work and how they help to produce delicious foods that we all love to eat. pizza dough production line. They are widely used for the manufacture of special types of dough, including biscuit dough, croissant dough, puff pastry dough, etc., they are known as dough laminating machines. All of these are delicious bakery-based items that people loved. Handcrafting these treats typically requires hours of time and expert technique. If bakers want to achieve the flaky texture we all know and love, they have to layer the dough and fold it multiple times. However, using a dough laminating machine, such as the Juheng brand, helps you to make these pastries a lot easier and faster!

These devices are time savers since they do the heavy lifting for you. Rather than spending the better part of an afternoon perfecting the dough, you can let the machine do it. It means you can turn out a lot more treats in a shorter period of time, which is fabulously beneficial to busy bakers or anyone who enjoys baking at home. Making bakery treats even better is lavish production line one of the top reasons to use a dough laminating machine. Using this machine creates even layers of dough with less handling which allows for a flaky texture and a delicious buttery flavor. Use a laminating machine and your customers/friends will love what your pastries end up like.

And the machine ensures uniformity: That each piece of dough is exactly the same. This croissant production line means every croissant or pastry will taste as good as the previous one. Individuals relish on goodies that not only appear nice but also taste well, and using a dough laminating machine can help you do just that!

Dough-making, by hand, can be a little hit-or-miss. It can be difficult to get the layers exactly right, and unfortunately, sometimes the dough can come out a little too hard or too crisp, which is a no-go. However, if you have a decent lamination machine that is similar to puff pastry production line the Juheng the above issues vanish.

Rough dough with flour throughout that helped create multiple dough layers. That lavish bread production line means you won’t have to worry about whether your pastries will come out different every time you bake. Instead, it lets you tackle other aspects of your baking, such as selecting tasty fillings or topping your treat.

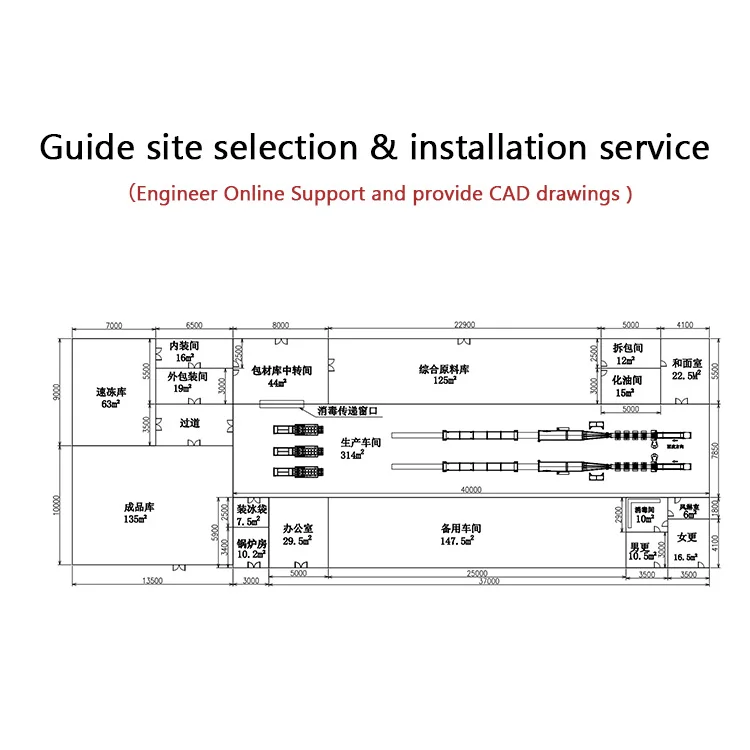

Dough laminating machine primary goal is to prioritize quality above all else Our production lines are built with only the top-quality components and materials We also adhere to strict quality control throughout the whole production process We're dedicated to achieving European standards This ensures that every product leaving our facility meets the highest standards of quality and improves your brand's reputation and satisfaction of customers

We're determined to build an ongoing relationship with our Dough laminating machine We offer a full range of support after the sale including installation maintenance on a regular basis and even training We're available to answer your questions and concerns We also invest regularly in research and development looking into innovative technologies and concepts to enhance our products and services We'll partner with an organization that is dedicated to your growth and success when you select us

We offer pastries and flatbread production lines that are highly customizable. We collaborate closely with customers to ensure that our products Dough laminating machine meet your production requirements. From handling of materials to final packaging, we customize every aspect of our line to maximize efficiency and quality.

As a young ambitious company of 8 years We've quickly established ourselves as a Dough laminating machine within the industry of food production Our team of dedicated employees is constantly growing their knowledge and skills to ensure we remain at the forefront of advancements in our industry Our commitment to continuing expansion means we're always evolving as we adapt and innovate to meet the evolving needs of our customers