Flat bread such as Roti is staple food in many parts of the world. Mass production of roti has become necessary to keep up with demand. The huge requirement of Chapatis in many parts of the world has led to a revolution in the food industry.with the introduction of a wide range of Lachha paratha/ roti canai production line, Peda Making Machine, Dough Kneading & Making Machine, Halwa Making Machine, Chapati Making Machine, ROTI Making Machine & All type of Food Processing Machineries. These lines are specifically constructed to churn out large quantities of roti, while making sure the quality that people love is not compromised.

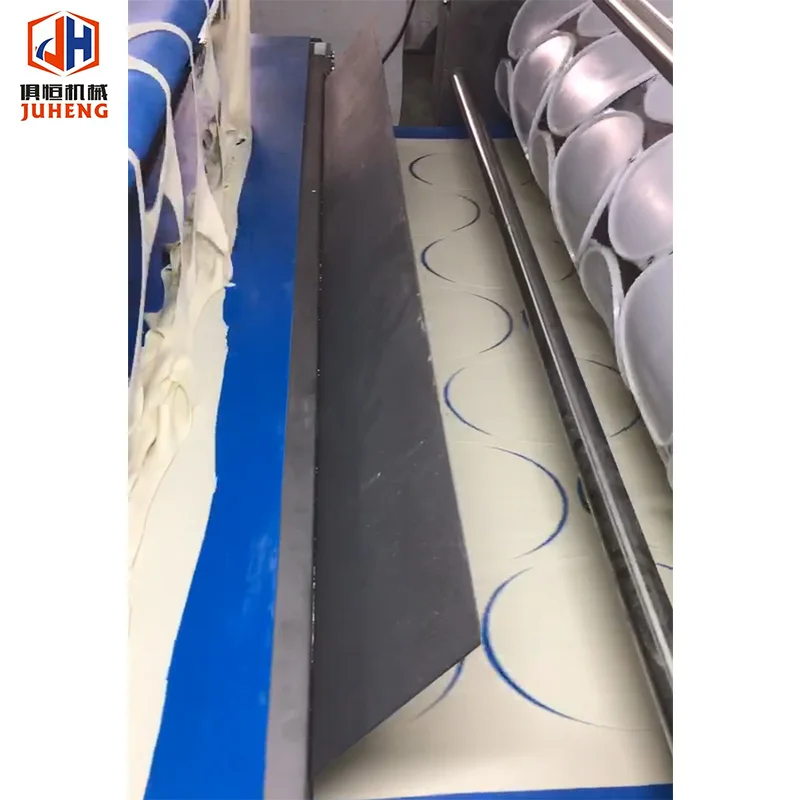

Juheng’s roti production line takes a technological approach to churning out lots of rotis really fast. This process is very organized. First you mix together ingredients like flour and water to create dough. Next, the dough is rolled into rotis. Then, the rotis are cooked to the appropriate temperature. That way, they turn out perfectly every time. We can cook many more rotis in less time using a machine compared to the traditionally handmade ones.

To ensure that each roti looks and tastes the same, Juheng employs special machines. These contraptions check the rotis as they are manufactured. If a roti isn’t perfect, the machine will see that and correct it. This matters, Pinto said, to ensure customers always receive good rotis. Juheng works hard to use new technology in order to ensure that the quality of the roti is high.

People and places have a variety of tastes when it comes to rotis. Juheng knows this, so they made their roti machines can adjust the way they make rotis. That means they can create different sizes, thicknesses, and even add special ingredients. This is perfect because Juheng can make rotis that will work for everyone no matter where they are or what kind of roti they prefer.

Lots of rotis come at a high price point, especially when you’re making a whole batch to sell to other people. Juheng’s machines save money because they operate quickly and don’t waste ingredients. They’re also made to last without falling apart. And that’s good for businesses, which means they’re not spending a bundle always fixing or replacing machines.

As a young ambitious company of 8 years We've quickly established ourselves as a roti production line within the industry of food production Our team of dedicated employees is constantly growing their knowledge and skills to ensure we remain at the forefront of advancements in our industry Our commitment to continuing expansion means we're always evolving as we adapt and innovate to meet the evolving needs of our customers

Our primary goal is to prioritize quality above all else We only use high-quality materials and components for our production lines and roti production line stringent quality control measures throughout the production process We're committed to achieving European standards This ensures that every product from our manufacturing facility meet most stringent standards This can boost the reputation of your company and increase the satisfaction of your customers

We are committed to building long-term partnerships with our clients We offer comprehensive support after the sale including installation ongoing maintenance and training Our support team is always there to help you with any queries or concerns We invest constantly in research and development of technology to improve our products and service You'll work with a business that is dedicated to your growth and success if you roti production line us

We offer pastries and flatbread production lines that are highly customizable. We collaborate closely with customers to ensure that our products roti production line meet your production requirements. From handling of materials to final packaging, we customize every aspect of our line to maximize efficiency and quality.