When you visit a bakery, theres' good chance that the fresh croissant in various shapes is on display. Croissants are rich, and buttery and flaky, which makes these pastries so yummy! We tend to forget, however, that perfect croissants are not an easy pastry. Recipes for every day white loaves are sometimes dismissed as 'pullman' loaf recipes but it actually really does need a certain amount of skill in making and shaping a perfect dough that the rise has to be done just perfectly - literally, you do require various tools. Alright, let's dig in and talk about the key materials you will need to make these delicious treats

Croissant dough is a lot of mixing to create. The dough should be smooth and shiny, which is necessary for proper rising. Mixed dough good croissants (Bad mix on the dough will give you shitty tasting food!) The baker's must-haves and prime examples of this are their dough mixers. This Juheng croissant production line is useful especially when you are mixing the bread dough as it gets mixed well into an even consistency. Once the croissant dough is mixed perfectly, its time mold them into beautiful croissants ready to bake.

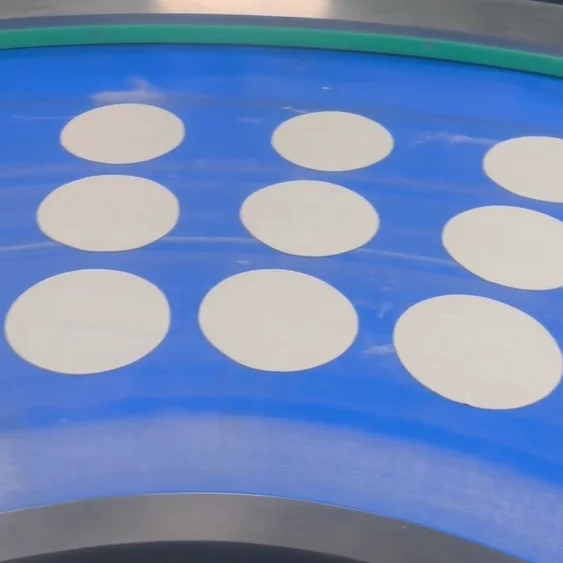

After kneading the dough together, it needs to be portioned out into balls. This is where a dough divider comes in. Dough dividers are the machines that cut it even slices. This step is absolutely critical – if your dough pieces are not all of the same size, they will NOT bake to be similarly sized croissants. Juheng croissant making machine is a device that divides the dough to assure an even number of croissants come out from the same quantity. This is important for a delicious, and beautiful croissants.

For perfect croissants, the dough must be a butter sandwich. That's how croissants get their real flakiness and lovely buttery flavour. Butter was another matter; this involved laying it onto the dough somehow. This is where the use of laminating machines comes in handy for bakers. The dough and butter are rolled with these machines, which layer them together in a specific manner. This is the process that gives croissants their flaky texture and delicious taste. With the help of a Juheng automatic croissant making machine laminating machine, fitters can guarantee that each individual croissant is as flaky and buttery correctly creating them a joy to consume.

Bakeries get creative with displaying their croissants!! Wow, that is why they have special contraptions to carve croissants into fun things. Bakeries can shape croissants as hearts, stars or even fun animals like reindeer. This makes the croissants look much nicer and shows that there is a bit of creativity involved which your customers will love Unique cutting tools provide an inexplicable advantage over other bakeries by helping you to minimize the monotony and make your bakery cool, so as to attract more customers who want something rare.

Once shaped, the croissants will need to proof. Now you need to roll and shape (prepare) the croissants for baking — this is what will make them flaky and light. Well, rising the croissants can get tricky. To get best results, outside temperature and humidity have to be just right. This is what proofing cabinets do. With this, each cabinet can be programmed digitally to control the temperature and humidity levels so that croissants rise exactly as per specification every time. Proofing cabinets help bakers produce croissants that are always airy and scrumptious.

Recognizing that each company is different We offer highly customized flatbread and pastry production lines. Our products are designed in close collaboration with our customers to ensure they are in perfect alignment with your Croissant equipment requirements. We optimize the efficiency of our production line by customizing every aspect from handling materials to packaging.

We believe in establishing Croissant equipment with our clients This is why we provide comprehensive after-sales service which includes installation education and ongoing maintenance We are always ready to assist you with your queries and concerns We also invest regularly in research and development exploring new ideas and technologies to improve our products and services You'll work with an organization dedicated to your growth and success if you choose us

We insist on quality over all else Our production lines are constructed up of only the highest-quality components and materials We also employ strict quality control throughout our entire production process We are committed to meeting Croissant equipment This ensures that every product from our manufacturing facility meet most stringent standards This will enhance the brand's image and improve satisfaction among customers

As a young ambitious company of 8 years We've quickly established ourselves as a Croissant equipment within the industry of food production Our team of dedicated employees is constantly growing their knowledge and skills to ensure we remain at the forefront of advancements in our industry Our commitment to continuing expansion means we're always evolving as we adapt and innovate to meet the evolving needs of our customers